When it comes to die casting, precision and accuracy are key – any defects or mistakes in the process can result in costly rework down the line.

In this blog, we’ll explore common die casting defects and how to ensure quality control in any die casting operation to prevent errors and ultimately create smoother part production runs. With this information at hand, you will be able to optimize your production processes better and ensure higher end-product quality

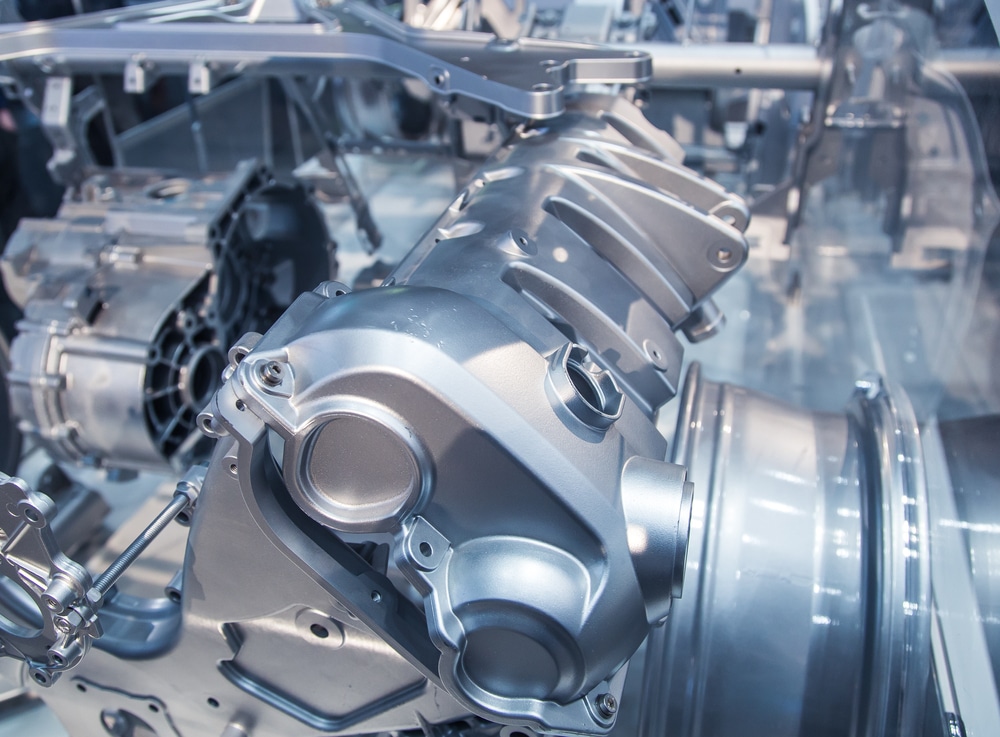

What is Die Casting?

Die casting is a manufacturing process that involves injecting molten metal into a die casting mold to create a desired shape. Many shapes can be made using it, such as engine blocks, door handles, and wheels. Small and medium-sized parts are typically processed using this method.

Compared with other manufacturing processes, such as machining and stamping, this method is faster and more efficient. The die casting process is versatile in that it can be used to manufacture numerous parts and products.

Common Die Casting Defects

While die casting is an efficient and cost-effective way to produce metal parts, it can also result in defects if not done correctly by your die casting manufacturers. Some common die casting defects include porosity, cold shuts, misruns, and flash:

Porosity

Porosity is a die casting defect that occurs when gas bubbles become trapped in molten metal during the injection. These gas bubbles can cause the finished part to be porous or have small holes on the surface. Several factors, including improper mold design, incorrect metal temperature, or insufficient venting, can cause porosity.

Cold Shuts

Cold shuts are another type of die casting defect that occurs when two streams of molten metal do not fuse properly. This can happen if the metal is at a different temperature or if the mold needs to be designed correctly. It is also possible for cold shuts to be caused by contaminated metal or mismatched metals.

Misruns

Misruns happen when the molten metal partially fills the mold cavity. Several issues, including poor mold design, inappropriate metal temperature, or insufficient ventilation, might cause it. Misruns can also happen due to contaminated or mismatched metals.

Flash

Flash is a thin layer of excess material that forms on the edge of the die casting parts. Various factors, such as poor mold design, incorrect metal temperatures, or insufficient venting, can cause this.

How to avoid die-casting defects

- Use the right die casting process: There are several different die casting processes, each with advantages and disadvantages. Choosing the right process for your project can help reduce defects risk.

- Use high-quality materials: Using high-quality materials is also crucial in preventing defects. Die castings are typically made from aluminum, brass, or zinc. These metals should be free from impurities and defects to produce the high-quality casting.

- Use proper design and tooling: Proper design and tooling are essential in preventing defects. The design of die castings must be precise to prevent problems during the casting process. It is also critical that the tooling used to create the casting is of high quality to avoid defects.

- Inspect the casting regularly: Inspecting the casting regularly during the manufacturing process can help to identify potential problems early on. This allows for corrective action to be taken before the defect becomes severe.

We’ll help you to avoid common die casting defects

The DyCast Specialties Corporation can assist you in avoiding all the usual die casting defects that result in product rejection. Die casting is challenging, but with our assistance, you can avoid all the usual mistakes that lead to items being rejected. We will demonstrate how simple it is to use this manufacturing technique to create high-quality parts. Contact us today to know more!

Comments are closed