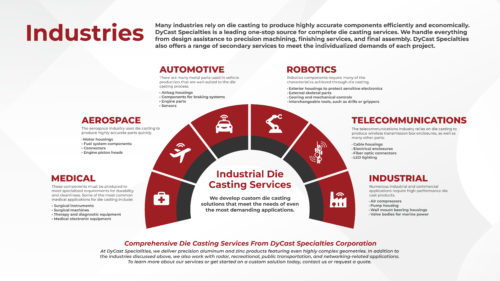

Many industries rely on die casting to produce highly accurate components efficiently and economically. DyCast Specialties is a leading one-stop source for complete die casting services. We handle everything from design assistance to precision machining, finishing services, and final assembly. DyCast Specialties also offers a range of secondary services to meet the individualized demands of each project.

Many industries rely on die casting to produce highly accurate components efficiently and economically. DyCast Specialties is a leading one-stop source for complete die casting services. We handle everything from design assistance to precision machining, finishing services, and final assembly. DyCast Specialties also offers a range of secondary services to meet the individualized demands of each project.

Industrial Die Casting Services

At DyCast Specialties, we understand the needs and quality standards of the diverse industries we serve. We develop custom die casting solutions that meet the needs of even the most demanding applications. Read on to learn more about industrial die casting and some of the industries we work with.