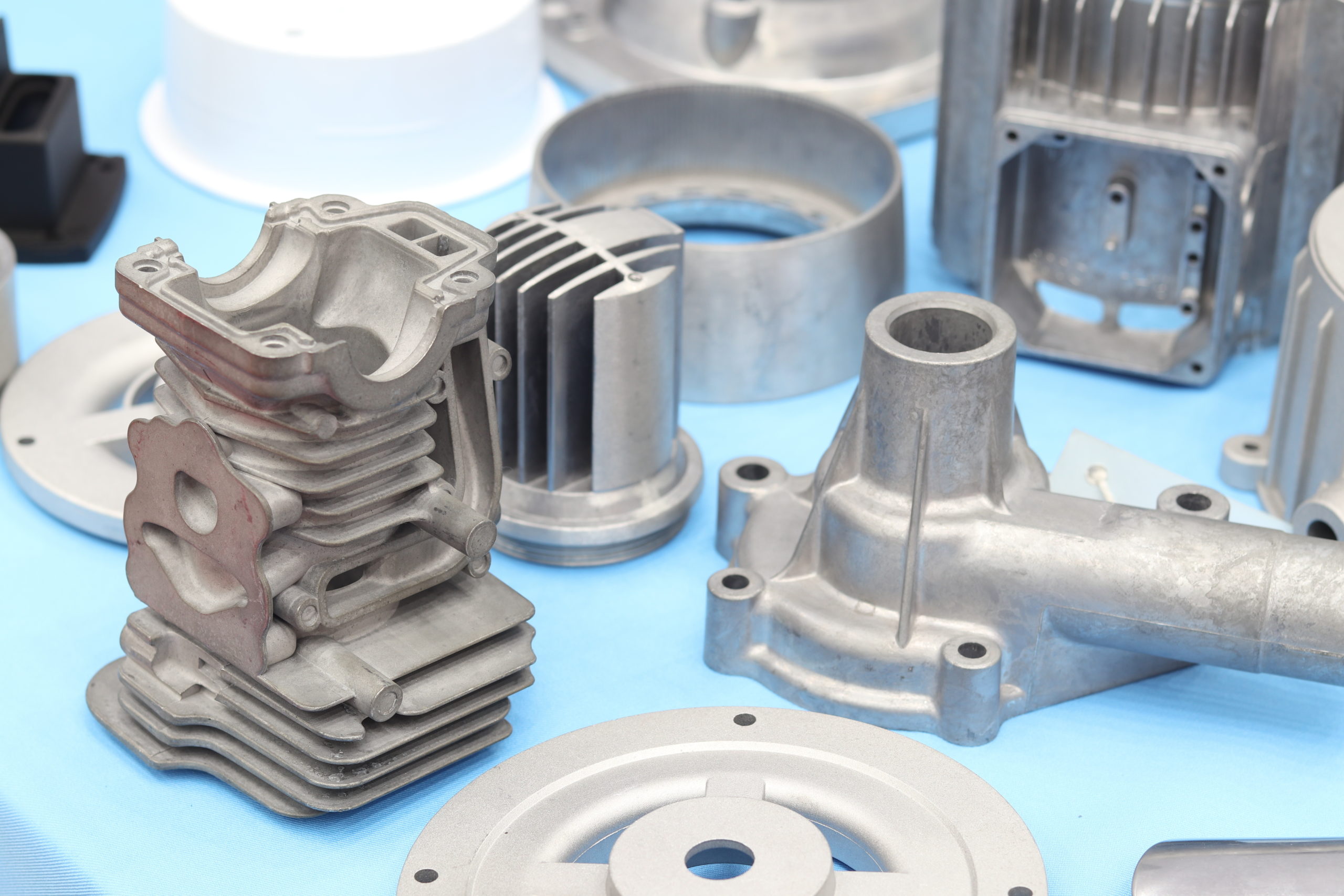

Die casting is a popular manufacturing process that produces car parts quickly and efficiently. It’s a versatile technique that can be used to create many different types of automotive die-cast parts. Some examples include airbag housings, components for braking systems, engine parts, and sensors.

Airbag housings

These are typically made from lightweight alloys to reduce their weight. This allows them to be easily carried around by vehicle occupants in the event of an accident. The material must also have superior impact strength so that it helps protect passengers during a crash.

Components for braking systems

Braking systems components are another type of automotive die-cast part often produced with this method. These pieces must be tough enough to withstand the high temperatures and pressures generated during use. The material must not corrode or wear easily when exposed to extreme temperatures, friction, and pressure.

Engine parts

These parts are important components that must be accurate and precise for a vehicle to perform optimally. Die casting is an excellent process for creating engine parts as it offers the level of precision needed for these specific components. It’s also an efficient production method that helps keep costs down.

Sensors

These are often used in vehicles as they provide feedback on various conditions within the car, such as temperature, speed, and fuel levels. To ensure optimal performance of these sensors, die-cast parts need to be extremely precise with low tolerances. This ensures that the components fit correctly into their places in the vehicle.