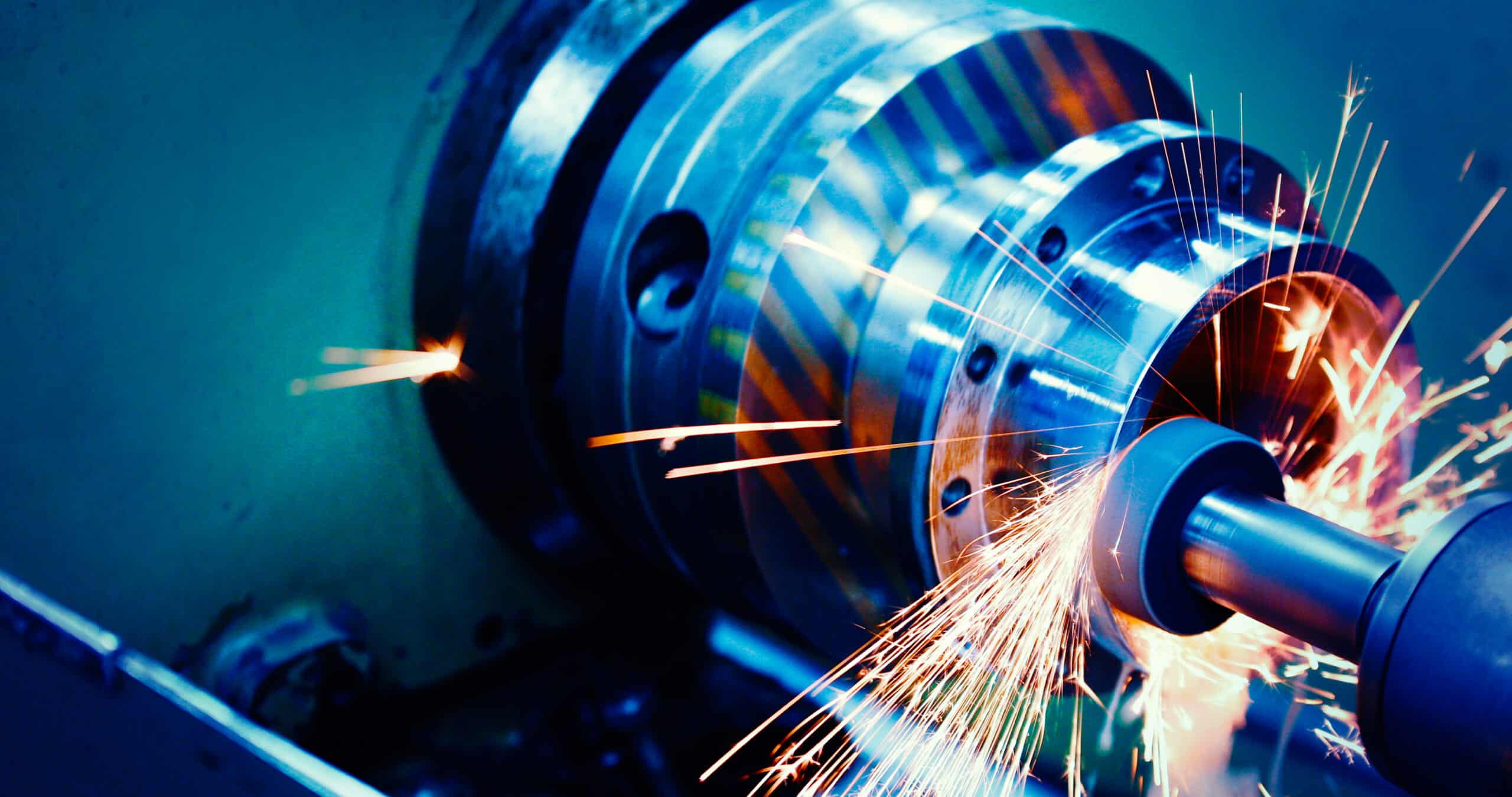

Computer Numerical Control, or CNC machining, is a versatile manufacturing process that leverages state-of-the-art technology to take raw materials and turn them into complex parts with tight tolerances and high precision.

CNC machines offer various capabilities, including milling, turning, drilling, cutting, and shaping. It can also accommodate almost any material type – from aluminum and plastic to more exotic materials like titanium, steel alloys, and more. The result is quality parts that meet customers’ exact specifications within the tightest of timeframes.

CNC machining process

At DyCast, we use CNC vertical milling machines to accurately and cost-effectively produce existing parts. We have adopted the latest CNC technology to ensure accuracy and repeatability in our CNC machining processes while minimizing any variation or errors between pieces created.

CNC technology is a sophisticated tooling method that relies on instructions generated by CAM software based on digital designs created using CAD software, allowing for unparalleled precision control for various tools.

By utilizing CNC technology, manufacturers can easily manage the design and construction process with accuracy and efficiency. As a result, the precision control afforded by CNC technology has revolutionized the industry’s capacity to create complex shapes and intricate parts with extreme accuracy.

Our CNC vertical milling processes involve:

- Vertical: We use vertical milling machines with highly accurate tool movement in three axes. This allows for a level of precision control unmatched by traditional machining methods.

- Horizontal: We use a CNC die cutting machine designed to cut workpieces in a horizontal plane while providing precision control.

- Multi-axis: Multi-axis machines offer various capabilities, such as drilling, milling, turning, and boring.

Advantages of CNC machining

CNC machining offers several benefits compared to manual labor and other manufacturing processes.

- Greater precision and accuracy: Our CNC capabilities can make parts with tight tolerances and high precision.

- Faster production times: CNC machining can substantially reduce production times with its quick, efficient process.

- Lower labor costs: The cost of labor is significantly lower when using CNC machining than manual labor.

- Reduced waste: CNC die casting machine reduces the waste generated by traditional manual labor processes.

- Better repeatability: CNC technology allows for greater consistency and repeatability in the production process.

Precision CNC machining capabilities from DyCast

At DyCast Specialties Corp., our CNC machining capabilities are some of the best in the business. We use state-of-the-art technology and equipment to create parts with tight tolerances and high precision.

Our extensive experience in CNC machining ensures that we can produce high-quality manufactured parts at competitive rates with reliability in both time and cost. With this expertise, we can guarantee customer satisfaction by providing exact production specs based on their requirements. Contact us today to learn more about our CNC machining capabilities.