High Pressure Die Casting

Capabilities

DyCast Specialties Corporation is a full-service die casting company that produces precision aluminum and zinc die casting products. We provide a comprehensive range of engineering solutions, including design ideas, prototypes, tooling, and production, as well as metal machining and finish. As a trusted die casting supplier, we’re able to deliver the highest quality and service to our clients thanks to our skilled team.

High-Pressure Die Casting

High-pressure die casting is a process in which it forces molten metal into a mold cavity under high pressure. The high pressure used in this process allows for a much more detailed and accurate final product.

According to Engineering.com, it is applicable for large-scale production and used for metals with high melting points, such as aluminum, brass, and cast iron.

The high-pressure die casting process begins with melting the metal in a furnace and injecting it into the mold cavity under high pressure. The metal cools and solidifies in the mold, then ejects the part. The high pressure in this process ensures the metal retains its shape and produces a robust, durable component.

Some advantages of high-pressure die casting include:

- The process produces parts with tight tolerances and smooth surfaces

- It is a fast and efficient way to produce large quantities of parts

- The process is adaptable to automation, which reduces labor costs

- High-pressure die casting is well suited for creating complex shapes

- Using the process with various metals, including aluminum, brass, and cast iron.

"*" indicates required fields

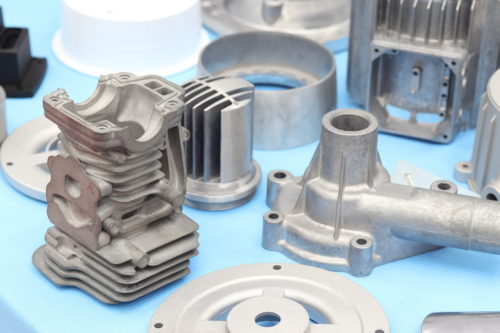

Aluminum Castings

Aluminum castings are versatile and essential for many industries. Our facility specializes in aluminum die casting services, creating complex geometric shapes for multiple applications.

We offer small, medium, and large die casting parts, weighing up to 10 pounds. Our machine sizes range from 600 to 725 tons.

We work with the following aluminum alloys:

- 380

- 383

- 413

We operate dedicated high-pressure aluminum die casting service cells. These include 600–725 ton die casting machines, 600 LB/hour 4800 LB capacity furnaces, and maintain tight tolerances of +/- 0.0025. Mold longevity can range from 40,000 to 100,000 shots, depending on part and mold complexity.

Zinc Castings

When it comes to creating complex yet durable metal parts, zinc castings are in a league of their own. ThoughtCo states that various products have zinc alloys, such as corrosion-resistant marine components and musical instruments. Able to reproduce even the most intricate shapes, zinc castings are applicable for small to medium-sized parts.

Our zinc die casting services rely on high-pressure alloy cells, producing parts that are both strong and wear-resistant. With mold longevity up to 1,500,000 shots, these components offer lasting value.

We specialize in several zinc alloys:

- Zamak 3

- Zamak 5

- Hybrid ZA-8

- Hybrid ZA-27

Aluminum or Zinc: Which is Best for Your Die Casting Needs?

Choosing between aluminum and zinc depends on the unique requirements of your project. As an experienced die casting manufacturer, DyCast Specialties offers both materials through our high-quality die casting services, helping you determine the best fit based on performance, budget, and design complexity.

Aluminum is ideal for lightweight, corrosion-resistant components with excellent thermal and electrical conductivity. It’s often used in automotive, electronics, and aerospace die casting products where strength-to-weight ratio and heat resistance are critical.

Benefits of Aluminum:

- Lightweight and strong

- High operating temperature resistance

- Excellent corrosion resistance

- Great for thin-walled designs

Zinc offers exceptional dimensional stability, making it perfect for intricate, high-precision parts. As a die casting supplier, we often recommend zinc for projects requiring low tooling costs, long die life, and superior surface finishes.

Benefits of Zinc:

- Outstanding surface detail and finish

- Long die life and low casting temperature

- Ideal for small, complex components

- Cost-effective for high-volume runs

Still unsure which alloy suits your needs? As a trusted American die casting company, DyCast Specialties will guide you through material selection to ensure the success of your project.

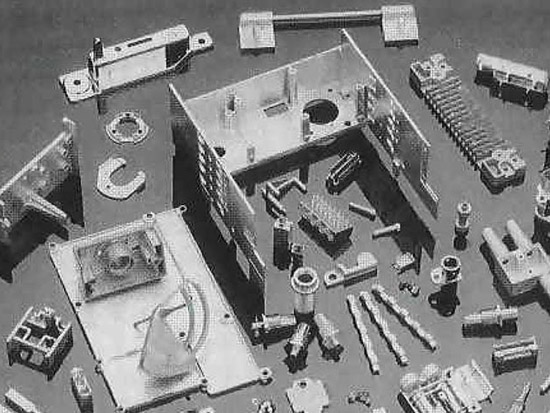

Tooling Construction

The quality of your tools impacts the quality of your final die casting work. That’s why DyCast Specialties—an experienced die casting manufacturer—only uses premium materials and construction methods for tooling, molds, and dies.

We use H-13 tool steel for all molds, heat-treated to 46-48 R/C for durability and longevity. Our in-house and partner tooling teams deliver high-performance results that meet or exceed expectations.

Tooling Concept and Equipment List

Our tooling concepts are as follows:

- 10″ x 12″ Standard DME Unit Dies

- 12″ x 15″ Standard DME Unit Dies

- 12″ x 15″ HD DME Unit Dies

- 15″ x 18″ Standard DME Unit Dies

- 15″ x 18″ HD DME Unit Dies

- 8″ x 8″ House Inserts

- Standard Cavity Retainer Sets

The following is a list of our equipment:

- 8 – 06 ton Trim Press

- 3 – 08 ton Trim Press

- 2 – 10 ton Trim Press

- 2 – 12 ton Trim Press

- 1 – 20 ton Trim Press

- 1 – 30 ton Trim Press

- 1 – 35 ton Trim Press

CNC Machining Capabilities

DyCast Specialties offers a wide range of CNC machining capabilities to create your needed parts.

We use state-of-the-art software and equipment, including:

- Our facility has three CNC Vertical Milling machines, each capable of producing high-quality parts and components.

- Our machining center is located in-house and has a tolerance level of +/- 0.00025 inches.

Finishing and Deburring

DyCast Specialties offers various finishing and deburring services to create the perfect product for your needs.

We offer three types of vibratory finishing:

- Vibratory finishing: Removes burrs, sharp edges, and other imperfections from metal parts and components, smoothing out the part surface making it ideal for cosmetic applications and best used on small, medium, and large castings.

- Tumbler finishing: This method uses a rotating drum to smooth and polish the surface of metal parts. It works excellent for deburring small casting components.

- Cryogenic Deburring: This process uses liquid nitrogen to remove flash from metal parts. Castings that are small to medium work best with this method.

We also offer various protective coatings to guard your die casting products from environmental factors.

Additional Processes

DyCast Specialties helps you create the perfect product by customizing it to your needs and preferences.

-

-

Annealing

-

This process relieves internal stresses in metals caused by heat treatment, welding, or machining. It makes the metal more ductile and less brittle and improves its machinability.

-

-

-

Shot Bead Blasting

-

This process uses steel shot to remove surface impurities and create a smooth, even finish. The advantages of shot bead blasting include a clean surface, improved adhesion, and increased corrosion resistance.

-

-

-

Chromate Conversion

-

Adding multiple coats and cleanings creates a thin, protective layer on the surface of the aluminum and other metals. It improves corrosion resistance and durability.

-

-

-

Clear Anodizing

-

This process creates a protective layer on the surface of aluminum parts. It is ideal for applications where the cosmetic appeal is essential. Clear anodizing provides advantages such as many color choices, extended service life, and improved corrosion protection.

-

-

-

E-Coating

-

This method gives a protective covering to metal components widely used in the automobile and appliance industries. E-coating offers advantages such as increased corrosion protection, improved durability, and a wide range of color choices.

-

-

-

Black Zinc Chromate

-

This plating process gives a black finish to metal parts often used for cosmetic purposes.

-

-

-

Bright Zinc Chromate

-

This plating process gives a bright, shiny finish to metal parts also used for cosmetic purposes.

-

-

-

Yellow Zinc Chromate

-

The plating process gives metal parts a yellow finish.

-

-

-

Liquid Paint

-

This process gives a smooth, even finish to metal parts. It is available in a wide range of colors.

-

-

-

Pad Printing

-

This process allows for transferring complex designs and patterns onto metal surfaces.

-

-

-

Powder Coat Paint

-

This technique leaves metal components with a smooth, uniform appearance. There are a variety of colors to choose from.

-

-

-

X-Ray

-

We offer in-house X-Ray capabilities to ensure the quality of your product.

-

-

-

Assembly

-

We offer various assembly services to put your product together.

-

We're the best because we put you first

DyCast Specialties offers a wide range of capabilities to meet your needs. We have a team of experts who can assist you in designing and developing your product.

If you’re looking for a reliable die casting supplier that provides full-service, American die casting solutions, don’t hesitate to contact us. Request a quote today and discover how our die casting manufacturer capabilities can bring your product to life.