Telecom Industry

Fiber optic connectors, cable housing solutions, LED lighting, industrial electronic terminals, and telecommunication processors are found in many electronic projects. One of the industries that rely on these devices is the telecommunications sector. As die casting specialists, DyCast Specialties can design and develop advanced telecommunication products based on your project’s needs and specifications.

Essential Telecommunication Components by DyCast Specialties

Telecommunications encompasses numerous industries, including internet service providers, radio and television, broadcasting, and Voice over Internet Protocol (VoIP). These handle substantial operations requiring telecom devices such as routers, switches, and other networking equipment. Some of these are made through die casting, which we’re experts in.

Die casting is a commonly used manufacturing procedure for creating complex telecommunication parts and components. Through our streamlined process and rigorous quality control system, we can produce outcomes that will improve your bottom line.

Advantages of Die Casting for the Telecommunications Industry

The die casting process is incredibly beneficial for the telecommunications industry. With its ability, we can deliver superior-quality products, regardless of their design and size. Die casting is the ideal solution for complicated and detailed projects, and it has innumerable advantages and desirable characteristics that make it the perfect manufacturing process.

Some benefits of die casting for telecommunications include:

- Complex net shapes: Die casting allows for complex and intricate net shapes, making it suitable for creating telecommunication components.

- Consistent quality: Die casting ensures consistent and high-quality products over high volume or large batch productions.

- Precision and accuracy: Die cast parts have precise dimensions and tight tolerances, so demanding telecommunications businesses prefer it over other manufacturing methods.

- Cost-effective: Die casting is affordable, especially in large production runs. It allows for the production of high-grade products at a lower cost.

- Advanced equipment: At DyCast Specialties, we utilize cutting-edge machines and equipment to accomplish results that will drive success to your business.

Typical Applications of Die Cast Telecommunications Parts

Maintaining steady and constant communication is crucial in the telecom industry. It’s the main reason why exceptionally-made telecom devices are necessary to sustain the diverse applications and operations found in the sector.

Some of the common applications of die cast telecommunications parts and components include:

- Parts for wireless devices

- Bluetooth-enabled items such as headsets, keyboards, and speakers

- Radio Frequency (RF) connectors and adapters

- Satellite communication parts

- Switching devices and components

- Voice command parts and components

- Fiber optic components

- Cable housings

We can produce high-performance products that will take your telecommunications projects to the next level. With strict quality control and a streamlined manufacturing procedure, our team can handle low or high-volume projects and deliver consistent results that can support even the most vital operations.

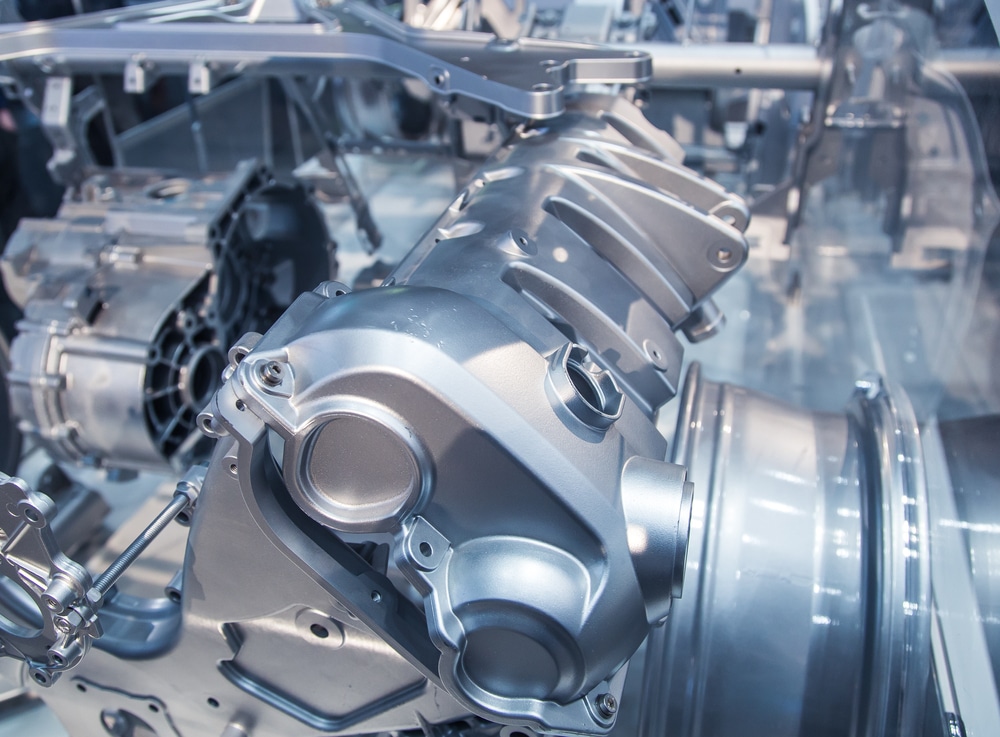

Proudly Serving the Aerospace Industry

The aerospace industry is one of the multiple industries we serve that utilize the die-casting method due to its numerous benefits. Die casting is a popular manufacturing technique where metals are forced into a casting mold at low melting points. It is an excellent metal fabrication option because no extra tooling is required.

Why opt for die casting for aerospace components? Below are the benefits you can reap:

- We can easily mold complex parts

- The ability to manufacture multiple parts

- Cost-effective and affordable solution

- Faster production

- Different wall thicknesses

- We can use recyclable materials

Apart from the benefits mentioned above, we can also work on tight tolerances. It means that our parts are precise and accurate, which is very important in the aerospace industry due to its demanding nature. The products undergo stringent quality control procedures, ensuring the components are made to your specifications.

Applications of Die Casting for the Aerospace Industry

Our team specializes in producing components or parts for the aerospace sector with our die-casting process. It allows us to manufacture products that are second to none. Plus, die-cast products are used for a variety of applications.

Some of the most common applications are the following:

- Turbine engines

- Engine piston heads

- Airframes

- Motor housings

- Landing gear

- Connectors

- Fuel system components

Our die-casting process is ideal because it efficiently creates parts. So whether you require small or big batches, we can provide them without wasting time since the overall process is fast. Additionally, the results are durable, reliable, and precise.

Trust Die Casting Experts to Create Top-Grade Telecommunications Solutions

DyCast Specialties are professionals in the die casting process and are proud to offer high-quality telecommunications products for your unique projects and applications. From design, manufacturing, quality control, and delivery, we ensure a comprehensive service that will take your business to new heights.

For more information about our capabilities, contact us today. You may also request a quote so we can start your project immediately!

Industries Served

At DyCast Specialities, we offer our premier die casting services to a diverse number of industries.