High Pressure Die Casting

Aluminum Die Casting

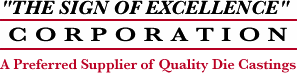

The aluminum die casting process forms precision metal parts using high pressure to completely fill all cavities within a mold. High pressure die casting works with numerous non-ferrous metals, such as aluminum and magnesium, among others. The die itself is made from tool steel to ensure long-term functionality with minimal production wear. This fabrication method provides an ideal solution for producing complex designs in high volumes.

At DyCast Specialties Corporation, we specialize in providing high–quality aluminum die castings for a wide variety of industries and applications. As an experienced aluminum die casting manufacturer, we are committed to delivering precision and durability, standing out among leading aluminium die casting companies in the U.S.

What is Aluminum Die Casting?

Aluminum die casting is a manufacturing process that forces molten aluminum into precision-engineered steel molds under high pressure. This method produces strong, lightweight, and complex components with excellent surface finishes and tight tolerances. Die cast aluminum parts are ideal for high-volume production due to their consistency and durability. Commonly used in automotive, electronics, and industrial applications, aluminum die castings offer outstanding dimensional accuracy, corrosion resistance, and thermal conductivity. As a trusted aluminum die casting manufacturer, DyCast delivers reliable solutions specific to your performance and cost requirements.

Why Aluminum?

Aluminum sees frequent use in die castings for producing lightweight, intricate designs. As a trusted aluminum castings supplier, DyCast Specialties works with the following aluminum alloys:

- 380 Aluminum: This popular alloy is both versatile and cost-effective. The A380 die cast aluminum is widely used in many industries for its excellent fluidity and strength.

- 383 Aluminum: This alloy offers greater workability than aluminum 380, especially for filling dies and molds

- 413 Aluminum: The 413 alloy is the most fluid aluminum alloy available, ideal for filling complex molds under pressure without gaps.

Regardless of the specific type of aluminum selected for individual projects, aluminum in general offers various beneficial characteristics:

- Conductivity. Aluminum conducts electricity and thermal energy well.

- Dimensional stability. This metal maintains good dimensional stability, even in parts with very thin walls. Aluminum’s stability also makes it an excellent choice for complex parts.

- Mechanical properties. Aluminum offers a good degree of hardness, shear strength, and tensile strength. These and other mechanical properties make aluminum a good choice for commercial and industrial parts that require reliable long-term performance.

- Resistance to corrosion. Aluminum resists corrosion and oxidation, making it useful for mitigating the risk of rust in indoor or outdoor applications.

- Strength. Aluminum is a strong metal with an excellent strength-to-weight ratio, even maintaining its strength at high temperatures.

- Weight. Aluminum is a lightweight metal, especially compared to steel and other popular manufacturing materials. This is important for designing fuel-efficient vehicles, aerospace parts, handheld consumer goods, construction elements, and other products where lower component weight may improve performance.

"*" indicates required fields

Common Applications

A wide variety of industries rely on aluminum for its versatility and compatibility with the die casting process. Some of the most popular applications of aluminum die casting parts include:

Appliances

Die casting suppliers like DyCast produce identical and interchangeable parts, which is crucial for mass-manufactured consumer appliances.

Appliances

Die casting suppliers like DyCast produce identical and interchangeable parts, which is crucial for mass-manufactured consumer appliances.

Automotive

Aluminum alloy die casting produces strong and lightweight automotive parts, enhancing fuel efficiency for automobiles and heavy trucks.

Automotive

Aluminum alloy die casting produces strong and lightweight automotive parts, enhancing fuel efficiency for automobiles and heavy trucks.

Electric Motors and Fluid Pump Motors

Aluminum has excellent dimensional stability, even at the high temperatures found in motor and pump operation.

Electric Motors and Fluid Pump Motors

Aluminum has excellent dimensional stability, even at the high temperatures found in motor and pump operation.

Hand Tools

Aluminum tools are lightweight, strong, and easy to handle.

Hand Tools

Aluminum tools are lightweight, strong, and easy to handle.

Hardware (Fasteners)

Aluminum fasteners withstand corrosion and environmental wear for a long-lasting hold.

Hardware (Fasteners)

Aluminum fasteners withstand corrosion and environmental wear for a long-lasting hold.

LED Lighting

Aluminum components conduct electricity well, contributing to the efficiency of LED lighting.

LED Lighting

Aluminum components conduct electricity well, contributing to the efficiency of LED lighting.

Medical/Healthcare

Medical devices need to be strong, lightweight, and rigid for easy use by medical professionals.

Medical/Healthcare

Medical devices need to be strong, lightweight, and rigid for easy use by medical professionals.

Military

Aluminum is a strong, cost-effective material choice for vehicle components, electronics, and structural components.

Military

Aluminum is a strong, cost-effective material choice for vehicle components, electronics, and structural components.

Recreational (Interior/Exterior Parts)

Aluminum fasteners, grommets, and other hardware are strong, rigid, and resistant to environmental damage.

Recreational (Interior/Exterior Parts)

Aluminum fasteners, grommets, and other hardware are strong, rigid, and resistant to environmental damage.

Retail Scanning

Die casting produces housings and hardware components used in retail scanning equipment.

Retail Scanning

Die casting produces housings and hardware components used in retail scanning equipment.

Robotic Automation

Industrial systems require strong, high-quality aluminum components that can integrate with other hardware.

Robotic Automation

Industrial systems require strong, high-quality aluminum components that can integrate with other hardware.

Security

Die casting aluminum produces high-precision components for smart locks, security cameras, and other security devices.

Security

Die casting aluminum produces high-precision components for smart locks, security cameras, and other security devices.

Video Conferencing.

Precision video conferencing system parts and housings are often produced using die casting.

Video Conferencing.

Precision video conferencing system parts and housings are often produced using die casting.

Quality Aluminum Die Casts from DyCast Specialties

At DyCast Specialties Corporation, we provide complete high-pressure aluminum die casting services. As a full-service die casting supplier, we manage the entire process, from the initial design through machining, finishing, and shipping. Our facility includes an in-house machining center with tolerance capabilities within +/- 0.00025 of an inch. Our additional processes include coatings, annealing, testing, inspecting, and assembly.

Contact us today to see how our quality A380 die cast aluminum components can support your project and how we can serve as your go-to aluminum castings supplier.

At DyCast Specialties, we provide complete high pressure aluminum die casting services.

Request a Quote TodayDOWNLOADS

Specifications

- Die Cast Alloys

-

-

Aluminum Alloys: 380, 383, 413

-

- Die Cast Cells

-

Aluminum – Hiqh Pressure:

-

(1) – 725 ton Die Casting Machine

(2) – 600 ton Die Casting Machine

(3) – 600LB/Hour – 4800LB Capacity Furnace

-

- Tolerance

-

-

+/- 0.0025

-

- Maximum Weight

-

-

10 Pound

-

- Tooling Construction

-

-

All molds are constructed from Premium H-13 tool steel and are heat treated to 46-48 R/C.

Tooling, molds & dies are produced through Dycast Specialties’ in-house tooling department, out-sourced tooling vendors, and overseas vendors.

-

- Mold Longevity

-

-

Up to 100,000 shots

-

- Tooling concept

-

-

10″ x 12″ Standard DME Unit Dies

12″ x 15″ HD DME Unit Dies

12″ x 15″ Standard DME Unit Dies -

15″ x 18″ HD DME Unit Dies

8″ x 8″ House Inserts

Standard Cavity Retainer Sets

-

- Equipment List

-

Trim Press Cells :

-

- 3-6 ton Trim Press

- 1-20 ton Trim Press

- 1-35 ton Trim Press

-

- 10 – 8 ton Trim Press

- 2-10 ton Trim Press

-

- CNC Machining

-

Machining Centers :

-

- 3 – CNC Vertical milling center with pallet changer

- 3 – CNC Vertical milling machine

Machine fixtures and CNC centers capable of producing tolerances of +/- . 00025

-

- Deburring

-

Tumble Deburring:

-

- Commercial type hardware finish.

- Utilizes a part on part barrel action to polish the casting surface, remove flash, and reduce sharp edges.

-

- Finishing

-

Vibratory Finishing:

-

- Premium visual cosmetics

- Utilizes plastic and ceramic medias to polish the casting surface and reduce sharp edges.

-

- Additional Process

-

-

Annealing

Assembly

Black Zinc Chromate

Bright Zinc Chromate

Chromate Conversion

Clear Anodizing

E-Coating -

Liquid Paint

Pad Printing

Powder Coat Paint

Shot Bead Blasting

X-Ray

Yellow Zinc Chromate

-