Best Aluminum Alloys for Die Casting

Aluminum Alloy Types and Characteristics

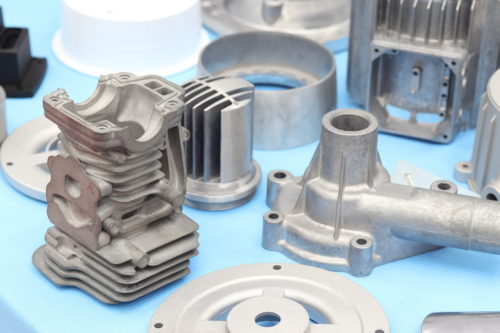

Aluminum die casting is a popular manufacturing process for quickly producing identical metal parts at high volumes. It is also a versatile and cost-effective method to produce parts with customizable finishes.

In die casting, molten metal is ejected at high speeds and high pressures into a die. Aluminum is an excellent material choice for this production method because it is easily workable and imbues the finished part with positive characteristics. Learn more about the most popular types of aluminum alloys, their most valuable characteristics, and common applications for aluminum die-cast parts.

Manufacturers often prefer aluminum alloys for producing strong yet lightweight metal parts at high volumes. Some of the most valuable characteristics of aluminum alloys include the following:

- Cost-effectiveness: Aluminum alloys are affordable and highly accessible. Even specialty alloys with added strength, resistance to damage, and other added features are cost-effective to acquire and use.

- Sustainability: Aluminum is recyclable. Manufacturers can repurpose used aluminum parts to create new components. They can also collect excess material around the castings and remelt them. This recyclability and sustainability reduce the environmental impact of every aluminum production project.

- Durability: Despite its lightweight nature, aluminum is very durable. The material is corrosion-resistant, heat-resistant, strong against physical damage, and can hold complex or intricate shapes.

Almost all aluminum alloys share these characteristics, but different alloys also have specialized features that make them appealing for specific projects. Some of the most popular aluminum alloys are:

- Aluminum Alloy A380: This lightweight, moderately corrosion-resistant alloy is used to build chassis, automotive parts, consumer goods, and other parts for high-heat applications. It can hold a variety of different shapes and surface finishes for different applications.

- Aluminum Alloy A383: Also called ADC12, this aluminum alloy is a popular choice for extremely intricate configurations because it responds so well to casting. Compared to A380, A383 is less durable but stronger and more resistant to cracking in high heat.

- Aluminum Alloy A360: A360 is built for industrial components. It has excellent fluidity and high-pressure resistance. Although it is harder to cast than A380, this alloy gives components good corrosion resistance and strength, including tensile strength, yield strength, and shear strength.

- Aluminum Alloy A413: This is the ideal metal for hydraulic cylinders and other highly pressurized parts. It’s also a top choice for intricate components and cold chamber die casting.

Applications of Aluminum Alloy Die Casting

Aluminum alloy die casting is a popular option for creating high-volume, dimensionally stable components across multiple industries. It’s important to work with a knowledgeable manufacturer that can help you determine the best aluminum alloy for your project. These are three of the most common applications for these parts.

Automotive Industry

Vehicles need strong, lightweight components that won’t break down despite exposure to high heat levels and potentially corrosive chemicals. Increasingly fuel-efficient cars and electric vehicles rely even more on these light, durable parts. Die casting can be used to create virtually identical chassis, engine components, and more.

Infrastructure Equipment

Because aluminum is thermally conductive, it’s commonly used for parts that need to offer a high degree of heat dissipation, such as networking and infrastructure components.

Handheld Device Components

Consumer goods and electronic devices also benefit from aluminum die casting, which can produce frames, structural elements, and intricate parts within the circuitry and controls.

Aluminum Alloy Die Casting from DyCast Specialties

At DyCast Specialties Corporation, we specialize in creating high-quality die-cast products from aluminum, zinc, and other metal alloys. We offer die casting services, engineering support, finishing services, in-house inspections, and more. Contact us today to learn more about our aluminum alloy die casting capabilities, or request a quote for custom pricing details.

What Die Casting Process Should You Use for Your Designs and Products?

Understanding Die Casting

Die casting is a manufacturing process in which metal alloys are liquified and injected into a reusable mold using extreme pressure. The finished piece is removed from the mold after cooling – sometimes requiring secondary processes. The process is fast, automatable, and able to produce high volumes of virtually identical components. This process is similar to injection mold in that it can create complex parts with specific geometries, however, die casting creates metal parts whereas injection molding creates plastic parts. Learn more about the different types of metal die casting, some of its most common applications, and how DyCast Specialties Corp. can help with your next project.

Types of Die Casting

Die casting is an efficient production method that produces high-quality, durable parts with considerable service life. There are several different types of die casting and it is important to know the differences when choosing a material and a casting method. The six most common types of die casting care:

Aluminum Die Casting

Aluminum is a versatile, cost-effective metal with a good strength-to-weight ratio. It also has a high melting point, meaning it needs a specialized process to accommodate it. Aluminum die casting uses cold chamber die casting, a process that specifically reduces the risk of corrosion by keeping the melting pot and the injector components separate.

The advantages of die casting with aluminum include:

- Quality: Aluminum is very formable and responds well to die casting processes. Manufacturers can create highly precise components that map accurately to the original design plan, even for parts with intricate geometries.

- Excellent product characteristics: The resulting parts are also durable, lightweight, and strong.

- Simplicity: Aluminum responds well to die casting, so it doesn’t need to undergo finishing or secondary processes.

Zinc Die Casting

Unlike aluminum, zinc die casting uses a hot-chamber process. In this form of die casting, the zinc is melted directly in the casting machine (rather than in a separate furnace) and then injected into the preformed mold. Zinc offers unique advantages for die-casted parts, including:

- Resistance to corrosion and general low-maintenance characteristics

- Excellent formability and castability, which makes it ideal for thin, intricate parts

- Sustainability because the metal is recyclable

- Excellent ability to conduct heat and electricity

Low-Pressure Die Casting

Unlike other processes that eject molten metal into molds at high pressures, this process works without feeders to create high-yield batches. This process is commonly used to create symmetric, circular aluminum parts, such as vehicle wheels.

Vacuum Die Casting

Vacuum die casting processes reduce turbulence and gas inclusions in the setting parts, which in turn results in strong, low-porosity components. Components that require heat-based finishing treatments are often vacuum cast.

Squeeze Die Casting

Metals with low fluidity are difficult materials to cast because they don’t efficiently fill the molds. Squeeze casting is ideal for these metals because once the mold is filled, it squeezes shut pushing the material into the deeper portions of the mold. Molten aluminum parts are often produced through squeeze die casting. The process results in products with stronger fibers and less fluidity.

Semi-Solid Die Casting

If you need parts with maximum possible density and virtually no porosity and turbulence, semi-solid die casting is the right choice. The metal is cut into smaller pieces and melted to a semi-solid state. Once in this state, a shot sleeve moves the material into the mold where it cures. It results in very precise components. Non-ferrous metals like aluminum and magnesium respond well to this process.

Die Casting Applications

Some of the most popular applications for die casting include parts for the following industries:

- Appliances: Die casting creates extremely precise components, which is ideal for small, compact configurations of moving parts.

- Automotive: Cars benefit from increasing light and durable metal parts that increase their fuel efficiency and performance.

- Electric Motors: EV motors often have aluminum parts because the metal is strong while still being lightweight.

- Hand Tools: Die cast parts are strong and durable without being brittle; they also have safe edges without relying on finishing and secondary processes to remove any burrs.

- Robotic Automation: Increasingly complex and flexible robots need precise, lightweight components that allow for complex motions.

- Security Components: Because die casting can work with a variety of metals, manufacturers can build everything from lightweight electronic security components to heavy-duty locks and tumblers.

Different applications and use cases often require different types of die casting and materials. For complex precision parts, for example, aluminum is often a good choice; for rugged tooling parts, heavy-duty carbon steels may be a better fit. Our design and engineering professionals can help you find the right process and materials for your die-cast design.

Die Casting at DyCast Specialties Corp.

Don’t let inferior die casting processes negatively impact your product quality or brand reputation. At DyCast, we specialize in full-service aluminum and zinc die casting projects. We prioritize complete customer satisfaction through excellent customer service, cost-effective services, expertise, and complete engineering support from start to finish. Contact us today to learn more about our capabilities or request a quote for pricing details.

Die Casting vs. Injection Molding

Which Process to Choose?

When manufacturing parts for your business, the first aspect to consider is the best manufacturing process for your application. Die casting and injection molding are two of the most popular choices, but they have specific pros and cons that influence how well they suit your project. While the main difference between die casting and injection molding is the material used, there are other key differences that we will take a closer look at here.

Die Casting Process

Die casting is a process by which a molten metal material is transformed into solid precision parts. First, a custom steel mold or die is developed and sprayed with lubricant to allow easier removal of the finished part. The metal—commonly aluminum, magnesium, or zinc—is poured into these steel molds using extreme pressure. The mold is then cooled, often through immersion in cold water. Finally, the die is opened and the finished component is removed.

Die casting offers many benefits for those needing precision metal components, such as:

- High level of accuracy

- High repeatability

- Ability to create complex shapes and details

- Minimal need for secondary operations

- Tight tolerances

- Reduced material waste

- Increased production rates

Depending on your project’s requirements, die casting may present the following cons:

- Limited raw material options (only works with metals with high fluidity)

- Higher initial cost due to custom mold design

- Limited casting size and weight

Injection Molding Process

In contrast, to die casting, injection molding utilizes liquified plastic to create precision parts. The injection molding process follows similar steps to die casting, including creating a mold of the part needed, using extreme pressure to inject the plastic or polymer into the mold, and cooling and removing the finished part.

Benefits of injection molding include:

- Quick turnaround times

- Greater variety of raw materials

- Use of fillers to enhance part strength

- Efficient processing

- Design flexibility

- High level of accuracy

These are some potential cons to using injection molding:

- Expensive upfront costs for obtaining injection molding machines and other equipment

- Small margin for error (requires a high level of design accuracy)

- Higher costs for larger injection molds

Die Casting at DyCast Specialties Corp.

While die casting and injection molding can both produce precision parts, it’s important to know the differences between the two processes to choose the one right for your application. To manufacture many plastic parts quickly, injection molding is your best choice. Those seeking the durability of quality metal parts should opt for die casting.

If you’ve decided that die casting is the best solution for your project, trust the experts at DyCast Specialties Corp. for high-pressure aluminum or zinc die casting solutions. We can create durable, high-quality parts for almost any application and provide you with other value-added services. Contact us to learn more about our die casting capabilities, or request a quote for your project today.